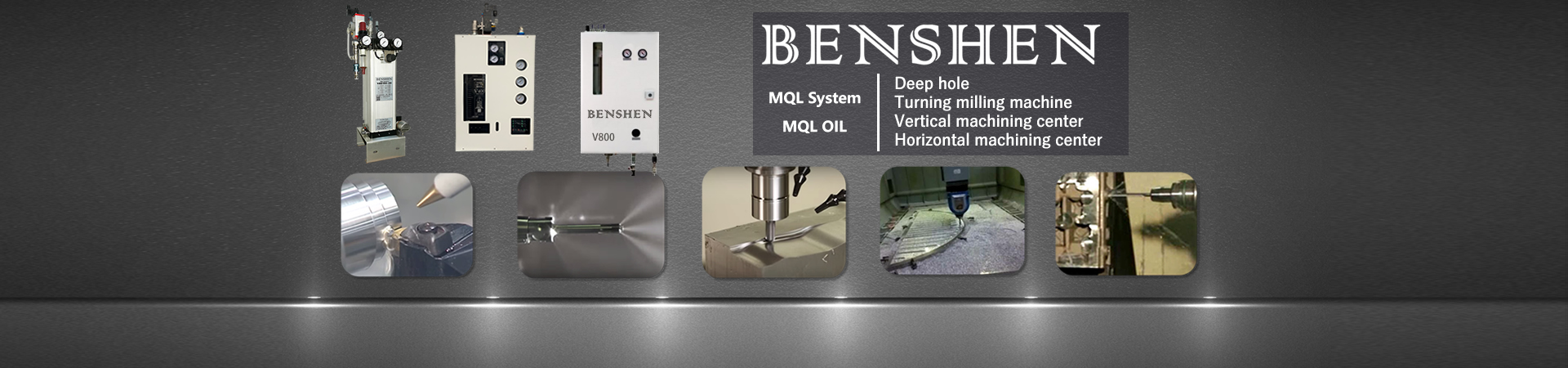

Application case of Benshen micro lubrication in small diameter deep hole drill

Specification and model 1:d1mm40 times diameter

Specification and model 2:d2mm30 times diameter

Processing material: Copper

Purpose of this improvement

1. The customer's copper processing, the environment inside and around the machine tool is very bad, so the environment is improved;

2. The high-pressure system of the customer's machine tool is easy to be blocked, which needs to be cleaned frequently. After being blocked, it is easy to cause the small drill bit to be blocked, which is easy to cause damage to the drill bit or reduce its service life;

3. No discharge, reducing the cost of waste liquid treatment for customers.

In this case, we adopted our customized V200 micro lubrication internal cooling system, and upgraded the original V200 micro lubrication system specifically designed for atomization of small-diameter drill bits, ensuring that the system can normally produce atomized particles less than 1 micron.

Description of improvement process

1. MQL micro lubrication system: customized V200 micro lubrication system

2. MQL micro lubricating oil: benshen-green-3905, which is a new product developed for copper and deep holes

3. Brand of CNC machining center: Mazak

4. Workpiece material: Copper

5. Tool handle: high precision internal cooling hydraulic tool handle for customer's own use

6. Drill bit: imported brand

Among the data and cases published by the same industry, there is no deep hole application case for 1mm diameter drill bit 20d and 2mm drill bit 30d or above in the world at present. Through this difficult challenge, the position of our micro lubrication system in the industry at home and abroad has been further consolidated.