Application case of micro lubrication in crankshaft machining of automobile parts

Application case of micro lubrication in crankshaft machining of automobile parts

Data in crankshaft machining

Component name: Engine Crankshaft

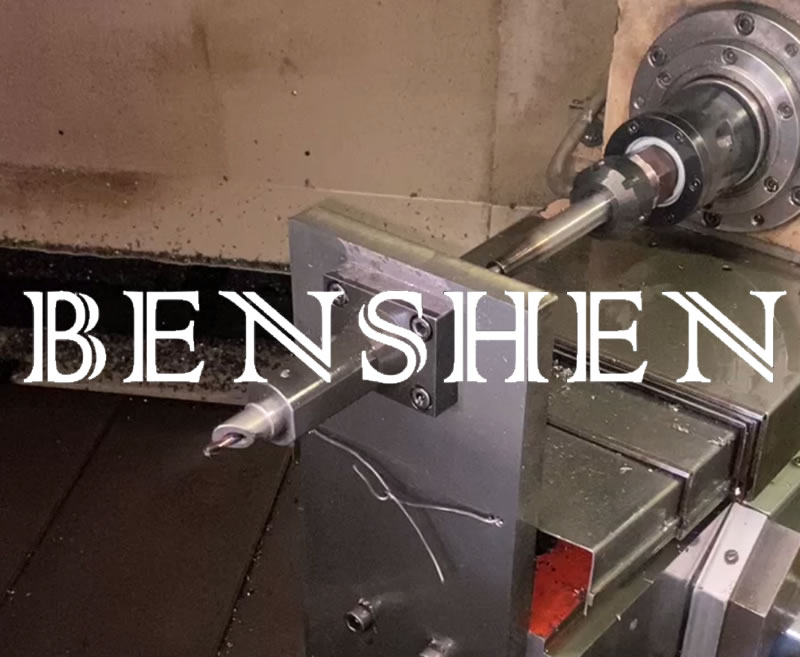

Processing procedure: crankshaft oil hole

Crankshaft machine tool: Shenyang crankshaft special machine

Micro lubrication system: V200 high pressure series (1.0~1.6mpa)

Tool size: d6~d8, depth: 30d

Workpiece material: 42cr

Tool life: can be increased by more than 30% compared with cutting oil

The application of micro lubrication in crankshaft processing has been very mature. In domestic and foreign engine crankshaft oil hole processing plants, most of them use micro lubrication. The performance of domestic micro lubrication system in crankshaft processing has exceeded that of foreign peers.

Advantages of using micro lubrication:

Cleaner environment

Longer tool life

Lower cleaning costs

5S cost

Lower

Advantages of Benshen micro lubricating products in crankshaft processing

V200 high pressure system, pressure 1.6Mpa, better improve lubrication and cooling effect

High performance micro lubricating oil, oil-3612, better lubricity, reducing friction between tool and workpiece

Due to the similar products at home and abroad, the cutting data finally obtained batch orders