Characteristics and advantages of MQL micro lubrication

2022-05-30 22:40:03

adminbenshen

28

Micro lubrication refers to the working condition with a very small amount. Its application reduces the pollution to the environment, simplifies the process, and makes it often necessary to use it in life. Our very familiar friend Benshen technology brings the characteristics and advantages of MQL micro lubrication.

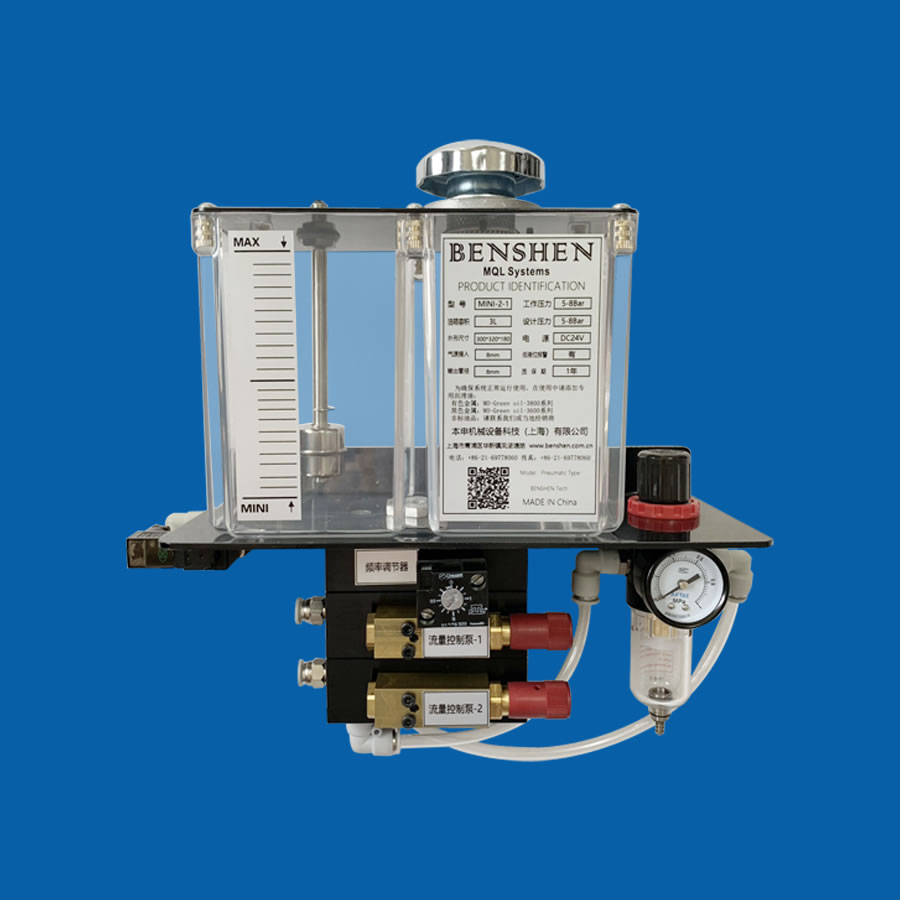

This application MQL micro lubrication system

Features and advantages

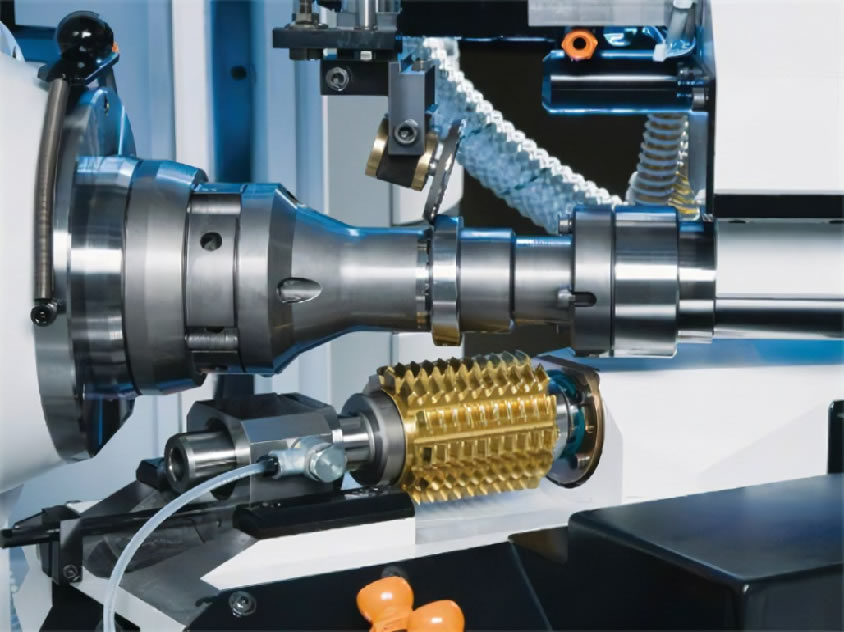

This MQL technology combines the advantages of dry cutting and traditional wet cutting: on the one hand, this MQL technology reduces the amount of cutting fluid to a very small amount, which not only significantly reduces the use cost of cutting fluid, but also minimizes the harm of cutting fluid to the environment and human body by using synthetic esters with high natural degradation as lubricants; On the other hand, compared with dry cutting, the MQL in this application has greatly improved the cooling and lubrication conditions in the cutting process due to the introduction of cooling and lubrication medium, and significantly reduced the wear between the tool, workpiece and chip, which helps to reduce the cutting force, cutting temperature and tool wear. This cutting technology, also known as semi dry cutting, has great prospects in the 21st century under the influence of the theme of green environmental protection.

Specific advantages and benefits

economic benefits

1. After the micro lubrication device replaces the coolant lubrication system, the cutting fluid recovery device can be omitted;

2. The micro lubrication system of Benshen uses a very small amount of lubricating oil. It can be vividly said that the oil consumed by a shift is about the size of a disposable cup if it is calculated as per 8 hours;

3. Increase the feed rate, improve the production efficiency of workpiece processing, and shorten the processing time by about 20-70%;

4. Extend tool life by 2-3 times;

5. The surface precision of machined workpiece is improved;

6. The power of this micro lubrication micro lubrication device is all from the compressed air at the processing site, without power loss. For large production lines, this item alone can save users a lot of money.

environmental benefit

After the micro lubrication device replaces the coolant lubrication system, no waste liquid will be discharged. It meets the requirements of energy conservation, consumption reduction and emission reduction advocated by the state, and is friendly to the environment. You will no longer have to worry about various social problems caused by being unfriendly to the environment.

Benshen micro lubrication

MQL micro lubrication in this application

Our familiar friend Benshen has brought us new articles. This introduction is about the characteristics and advantages of MQL micro lubrication in Benshen. Please continue to pay attention to us.