Performance requirements for quasi dry cutting lubricants

2022-05-30 22:49:18

adminbenshen

17

MQL can greatly reduce the friction between "tool workpiece" and "tool chip", inhibit temperature rise, reduce tool wear, prevent adhesion and improve workpiece processing quality. Few lubricating fluids are used, but the effect is very significant. It not only improves work efficiency, but also does not pollute the environment.

The amount of lubricant used in MQL method is very small. As long as the MQL technology is used properly, the processed tools, workpieces and chips are dry, avoiding post-processing. The clean and clean chips can be recycled after compression without polluting the environment. Therefore, it is also called quasi dry cutting.

Quasi dry cutting lubricating oil shall have the following properties:

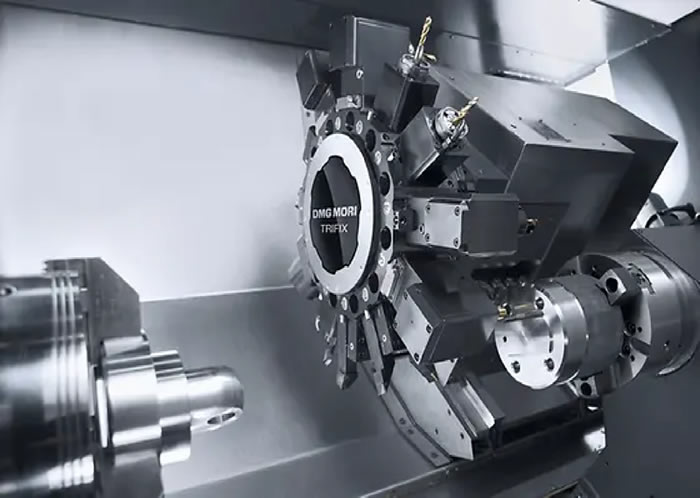

It can be firmly absorbed on the metal surface, play a good lubrication role and reduce the cutting resistance at the same time. The surface roughness meets the design requirements and improves the dimensional accuracy;

Good thermal conductivity, good cooling effect, can reduce the cutting temperature and prolong the service life of metal cutting tools;

Good rust resistance, no metal corrosion, no damage to the accuracy and surface roughness of machine tools and workpieces due to corrosion;

Cutting oil is non-toxic, non irritating, non harmful to operators, and has production safety;

Cutting oil has proper viscosity and good permeability;

It has strong versatility and can be applied to a variety of cutting methods and materials;

Low cost or no treatment of waste oil;